In the race to cut costs and offer more hygienic commercial and industrial cleaning services, facility managers are increasingly considering a new generation of autonomous machines.

One of the largest shopping centres in Australia, located on the Gold Coast, presents a daily challenge to maintain the highest possible cleaning standards.

However, the Trident Services Australia night cleaning crew which has that job now has a new team member who is making a difference – a Gausium Scrubber 75 robot.

It can run without intervention for almost five hours alongside a cleaning team that can now focus on more detailed cleaning tasks, rather than floor care.

“The twin problems of a labour shortage and a high minimum wage in Australia are both now much easier to manage while keeping the mall showcase clean,” says Tom Culver, Australian country manager for Gausium, which has about 5000 autonomous cleaning robots working around the world in facilities such as shopping malls, airports, schools, offices, shopping malls, hospitals and hotels.

The same Scrubber 75 machines have been used to clean many international sites, including the Mass Transit Railway network in Hong Kong. They can empty and top up water and charge themselves automatically without human assistance. Their sensors also allow them map out the best cleaning routes.

Other robots in the Gausium range include the Phantas (a compact all-in-one model with four cleaning modes), the Scrubber 50 (for smaller centres and supermarkets) and the Vacuum 40 (an autonomous vacuuming robot).

Chance to save time and money

The Gausium robots are part of a new breed of autonomous cleaning machines that are being rolled out in Australia and New Zealand as building services contractors and facility managers seek to save time and introduce efficiencies into their cleaning and hygiene workflows.

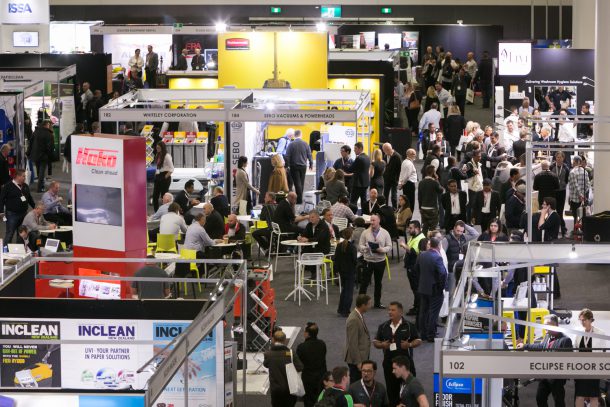

Brant Insero, the Chicago-based senior director of education, training, certification, and standards at ISSA, the worldwide cleaning industry association, says autonomous equipment clearly has a place within the cleaning industry and that organisations which embrace innovation have the chance to become industry leaders.

“Early adopters will have the ability to workload such equipment into their operations to reduce labour-intensive projects such as daily floor maintenance,” he says.

Nevertheless, Insero says any style of equipment has positives and negatives – and the robots have to be used appropriately.

“As an example, autonomous machines truly do save on labour in specific circumstances such as daily floor maintenance. This allows cleaning professionals to focus on detail tasks during their shift,” he says.

“(But) we have been hearing stories that supervisory staff need to be concerned about the efficacy of the autonomous machines as cleaning staff will turn them on and let them run without checking for preventative maintenance and performance levels.”

When considering adopting robotic technology, many cleaning businesses will be weighing up their investment versus return, according to Steve Bagshaw, CEO of i-team Australia and New Zealand.

For now, he believes smaller, cheaper autonomous machines may be more viable than larger, high-cost machines designed for industrial spaces.

In that vein, his business sells the Co-botic 1700, a programmable robotic vacuum cleaner featuring software which can follow detailed instructions on where to clean in a workplace.

“That’s what we see as the trend – smaller units with much lower risks and which are much simpler to use and map,” Bagshaw says.

“They’re a genuinely practical solution. They’re small enough that you can deploy them comfortably and you’re not worried that they’re going to take down a freestanding TV, or trap someone’s foot up against the wall. All those OH&S risks are taken away and the financial risk is almost reduced to zero.”

By contrast, Bagshaw says some facility managers are wary of spending tens of thousands of dollars on larger robots that may not be able to clean up close to walls because of their scale.

“When it’s a $50,000 investment, it’s a different ballgame,” he says.

“There’s certainly a lot of anticipation because robotics is an exciting concept. But the business-value case for those larger and more expensive robots – to deliver value for organisations – is not playing out yet.”

Advantages for building services contractors

As artificial intelligence enables technology advances, autonomous machine manufacturers and distributors have been advocating the advantages of their robots for cleaning and hygiene-related work. They point to ever-improving efficiency and productivity with robots.

Joe Camilleri, managing director of Central Cleaning Supplies, says the best robots are able to achieve consistent cleaning results, repeatedly.

“This translates to less water and chemicals used and visibly cleaner floors,” he says.

“Robots are able to free up personnel from repetitive floor cleaning, leaving them to focus more on detailed duties such as touch-point cleaning.”

Central Cleaning Supplies distributes the LionsBot range of autonomous machines, including LeoScrub (a scrubber that slashes water use), LeoMop (a quiet machine that leaves behind much drier floors), LeoVac (which has an optional HEPA filter for cleaner air), LeoPull (a robotic pulling machine which can drag around a 450kg bin), LeoRay (which disinfects surfaces through UV-C radiation), Rex (for large commercial spaces) and R3 Scrub (a new compact cleaning companion).

The machines can work around the clock and are known for their ease of deployment and monitoring, as well as their positive impact on productivity.

“Through a cloud-controlled app, the cleaners are able to receive notifications if there are any issues on the robots and issue remote commands,” Camilleri says.

“This effectively means that the cleaners can clean multiple places simultaneously.”

He says the best return on investment typically comes from facilities with extensive floor space, or areas that require frequent floor cleaning.

While robots provide an opportunity for cleaning contractors and facility managers to reduce labour costs and better manage repetitive tasks, Insero says there can be challenges. For example, some contractors struggle to house large equipment in their facilities because of storage constraints.

“Some regions of the world have unique architecture, which creates smaller working environments as well,” he says.

“If the customer allows for dedicated storage for the contractor’s autonomous equipment, this can help the contractor realign their labour to focus on tasks that will create higher levels of quality.”

Insero says the world is continuing “to shift toward cleaning for health”.

“To focus on this, contractors need to begin relying on technology to help achieve their normal soil-removal requirements.”

Changing perceptions

There has been resistance to autonomous machines from some cleaner and facility managers in the past. Historically, there were concerns that robots would come at the cost of human jobs, while the upfront costs of the technology worried some potential buyers.

Bagshaw admits that some facility managers have been turned off robotics because of poor-quality machines that were offered in the past. However, he believes the latest smaller robotic vacuums, in particular, have allayed some of those concerns.

Demand for such smaller robots will continue, according to Bagshaw, especially given labour shortages in markets such as Australia and New Zealand and some other international markets.

“With the labour markets so constricted globally in the western world at present, there’s such a shortage of staff. Therefore, people are embracing any ability to turn staff hours into higher productivity and payoffs by just getting the basics done with robots.”

Camilleri says users are much more confident operating the new-generation robots. They can now access more places, and the average cleaner can use the robots without as much specialised training.

“The ease of use now has surprised cleaners, so much so that with minimal training they can become proficient robot users.”

In making an investment in robotics, he advises buyers to shop around to get the best and most appropriate machine for their purposes.

“Another area to consider is the environmental footprint of the robots – namely, how much water it uses and the runtime,” Camilleri says.

“Look for a supplier that offers comprehensive technical support and provides around-the-clock service.”

Culver agrees that getting the right service and support is crucial for prospective purchasers of robots. He believes Australia is ready to embrace a new generation of cleaning robots.

“Australia is on the cusp of having a robot revolution here, with our high cost of living and relatively high minimum wage. It makes for a perfect setting for robots.”

Data deluge

Camilleri adds that autonomous machines offer “evidence-based work” in that they can provide detailed cleaning reports and data to validate the cleaning coverage and quality of their work. This means that contractors can better communicate cleaning goals with their customers and potentially gain an edge with tenders.

“Forward-looking cleaning contractors who invest and fine-tune their operations to incorporate robots to complement their workforce will be able to better deliver a much more competitive bid and thus gain an edge,” he says.

According to Insero, the ability for new robots to provide enhanced data and become integrated into other areas of the built environment can be a game-changer.

“If the challenge of ‘can you do more with less?’ continues to be a trend, experts will focus on providing solutions for the challenge,” he says.

“As an example, from 2021 we saw autonomous floor machines in retail environments also scanning the inventory on shelves as it passed by. This type of solution also allows contracts to embed themselves into the customers’ business even more.”

Insero encourages businesspeople in the cleaning industry to examine the benefits that autonomous equipment can deliver.

“Customer expectations are rapidly changing and so should your solutions.”

He says technology creates a working environment of curiosity, excitement and enhanced knowledge.

“We now have tools that will help younger professionals look at the cleaning industry differently. As an industry, I see autonomous machines, robotics, and integrated technology as a way to bring younger professionals into the workforce for our industry.”

This article first appeared in the July/August issue of INCLEAN magazine. Read the original article here.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at info@incleanmag.com.au

Sign up to INCLEAN’s newsletter.